Aluminum welding

Aluminum is a good conductor of heat and starts to melt rather quickly, so a hole can be burned through the metal if not welded correctly. Also, there is an oxide film on the metal, which begins to melt only at 2000 degrees. A so-called crater appears at the end of the weld. This defect can be corrected. We carry out work with professional equipment.

We recommend that you do not engage in such types of work on your own, but contact us. As a result, you will receive high-quality and beautiful, and most importantly, reliably welded aluminum parts of various sizes.

Stainless steel welding

From the welder when welding such metal, you must first make a neat seam. The problem is that stainless steel is a poor conductor of heat. Therefore, it gets very hot at the welding site. Also, during work, the metal expands greatly. If you leave a small gap between the blanks, the seam will turn out to be sloppy. And the metal itself can burn out.

Our specialists have sufficient experience and skill to carry out such work efficiently and correctly.

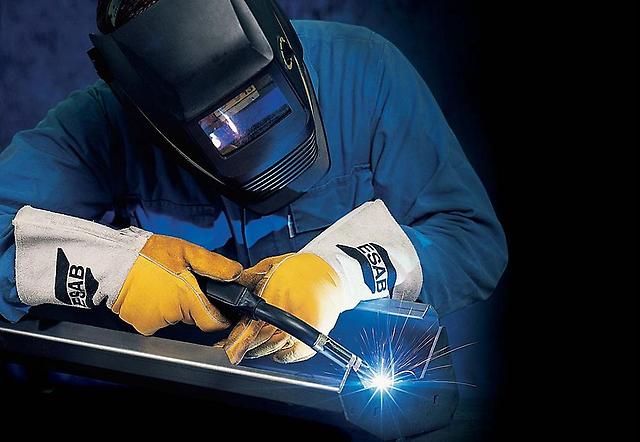

Argon welding is one of the fastest and most reliable ways to join all workpieces from any metal. But in order to do it efficiently and accurately, you need to have sufficient experience and practical knowledge. Therefore, it is almost always recommended to contact a specialist for this type of welding.

We offer quality assurance services for all work performed.